Pump the brakes on your busy day, because it’s movie time! One of my favorite YouTube channels, Engineering Explained, released a video on Porsche’s new braking technology (watch video here: https://youtu.be/ZCj83_uF9dE). Historically, carbon ceramic brakes are the pinnacle tech when it comes to transferring kinetic energy into thermal … or bringing cars to a stop. The German manufacturer is among a handful of other ultra-premium, high-performance manufacturers that continue to offer carbon ceramic brake rotors as an option on their vehicles today. In other words, it’s not accessible to the everyday consumer, but they’re still bringing Formula 1 and Le Mans Prototype braking tech to “mass” production. Problem is, F1 technology commands F1 prices. I don’t know about you, but I’d drop dead if I rolled into the service bay and was told I needed a $32,000 brake job.

With exception to the crippling expense of being a roughly $10,000 option, carbon ceramic is the perfect brake rotor material for performance applications. They’re fade free, they generate very little dust, and they take forever to wear. Race teams rarely have to replace a carbon ceramic rotor – even when threshold braking from 200-plus mph down to 40 mph repeatedly over a 24-hour period – like in the case of prototype racecars competing in the Vingt-Quatre Heures Du Mans (that’s the 24 Hours of Le Mans for you non-purists). When they do need to be replaced, it’s almost never because of wear. Compared to conventional brake rotors, which are way less expensive, four ceramic brake rotors weigh at a quarter of what one conventional cast iron rotor weighs. Let that sink in. We’re talking multiple orders of magnitude of unsprung weight and rotational-mass savings!

This is getting to manufacturing technology soon. Promise!

Brake rotors are very similar to cutting tools. Conventional brake rotors are like high-speed steel tools. To get more performance, you go with carbide. So, Porsche has essentially taken carbide cutting tool technology and put it on brake rotors. Now, we’d be going in the opposite direction of high performance if they made a full-size brake rotor out of carbide because that would be the heaviest option with the most rotational mass and most unsprung weight.

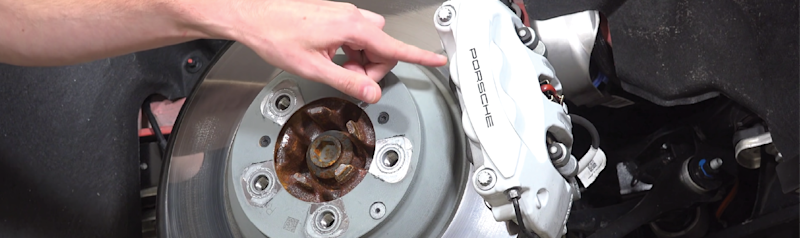

What Porsche has done is they’ve taken tungsten carbide powder (similar to the carbide material used in cutting tools), run it through what is, essentially, a rocket engine, out the rocket nozzle, and directed that jet of fire and tungsten carbide onto the braking surface of, essentially, a conventional cast iron brake rotor. This plates the cast iron braking surface with about 0.001 inches of tungsten carbide. It’s still expensive (it is Porsche, after all), but it’s far less expensive than going with full carbon ceramic brakes. Most of the benefits – with exception to the weight savings – but without the insane cost.

Performance benefits? Carbide versus iron or steel? Does this sound familiar? It should! Carbide versus steel brakes is almost the exact same sales pitch as carbide versus high-speed steel cutting tools! The latest and greatest the high-performance auto industry has to offer has taken a page out of the manufacturing industry handbook with a long-established concept! How cool is that? I wish you could see the smile on my face as I write this. I’ve always looked at brakes as a beautiful means to convert kinetic energy into thermal, but now I can see the correlation with material removal.

With carbide, you get longer life than conventional iron and steel, can push it harder, and will generate less chatter. They’re still expensive – $11,000 to replace all four rotors, but that’s better than the aforementioned $32,000 – and you lose out on the carbon weight savings; in fact, carbide is WAY denser, and thus, heavier, than steel, so the coated rotors will be slightly heavier than plain iron but lighter and less expensive than solid carbide rotors, thanks to the plating method. Maybe someday we’ll see carbide-plated, high-speed steel cutting tools? Maybe someday we’ll see conventional cutting tool coatings applied to carbide coated car brakes? What a time to be alive!