“ATI goes where robots go!” says Bob Little, CEO of ATI Industrial Automation in Apex, North Carolina. A longtime IMTS exhibitor, ATI worked with NASA’s Jet Propulsion Laboratory to develop the breakthrough Space-Rated Force/Torque sensor that plays a role in gathering samples from the planet’s surface – a key element in NASA’s Mars Exploration Program.

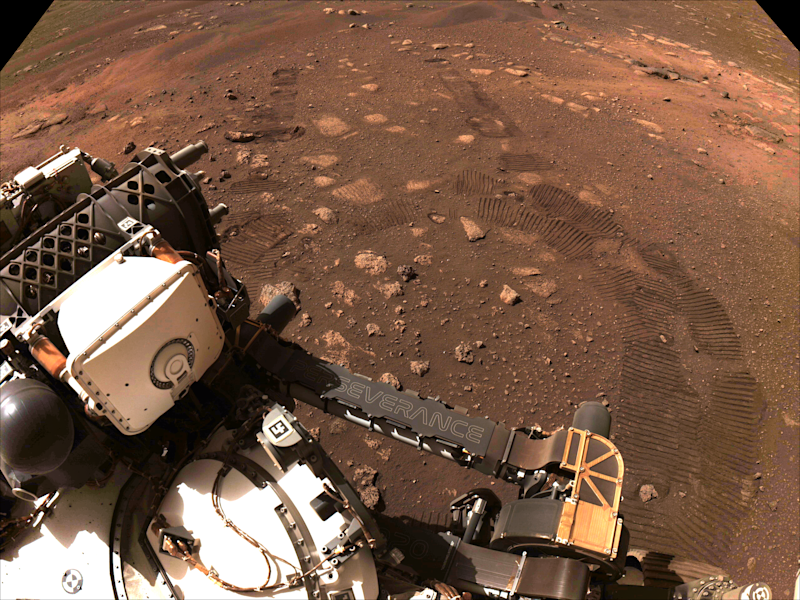

On Feb. 18, 2021, Little sent every ATI employee the official NASA link to watch the Perseverance rover land on the red planet. Undoubtedly, the landing was spectacular – a grand event to cherish, and one that will likely impact our future.

“We feel a huge sense of pride seeing our work come to fruition. Our engineers flexed every creative muscle to custom design the Space-Rated Force/Torque sensor. The launch and landing are just the tip of the iceberg,” says Little.

ATI’s sensor starts working once Perseverance’s automated system begins to collect, handle, and index the material it harvests from Mars’ surface. “We certainly exhaled when Perseverance landed,” Little continues. “Now we’re eager to see the sampling begin.”

ATI’s Force/Torque sensor integrates with the end effector on a small robotic arm, known as the Sample Handling Assembly (SHA), which inspects and seals samples in the rover’s onboard lab. With force sensing from ATI, the SHA is equipped to maneuver easily through the tight workspace inside the rover, performing demanding tasks with acute accuracy.

Often used in research and manufacturing industries, ATI’s Force/Torque sensors enable greater process control and provide process verification such as indicating that a pin is inserted properly into a fixture.

ATI knows how to engineer for challenging environments, having developed robotic tooling for nuclear decommissioning, foundries, underwater environments, food handling, and other diverse applications. The harshest environment they’ve faced, however, is the surface of Mars, with an average temperature of minus 81 F and rugged terrain. ATI designed the space-rated sensor with signal redundancy and temperature compensation to ensure accurate resolution of forces and torques. To test these breakthrough features, ATI’s team designed specialized calibration equipment and conducted product trials with 24-hour surveillance.

They also used components made of thermal-stable, low-outgassing materials to fortify the sensor against drastic environmental fluctuations and to prevent cross-contamination of samples.

“Since repair opportunities are limited on Mars, the ATI Force/Torque sensor requires outstanding engineering,” says Stephen LaMarca, AMT Manufacturing Technology Analyst, co-host of the AMT Tech Trends podcast, and star of IMTS Network's Road Trippin' with Steve. “From ATI’s sensor to the rover’s parachute-embedded secret message – 'dare mighty things’ – I have a feeling Perseverance is going to show us some mighty technology.”

To see where the sensor is located within the Perseverance rover, watch this video: https://www.ati-ia.com/company/NewsArticle2.aspx?id=724930791.

Visit https://mars.nasa.gov/ to learn more about Perseverance.