When manufacturers upgrade machinery to a newer model, the old equipment sometimes sits collecting dust or is disassembled for parts. To help a customer swap out an old micro milling machine after delivery of a new unit, KERN Precision had a better idea: donate it to a worthy community college. That donation is the catalyst for a unique curriculum in ultraprecision and micromachining that teaches an increasingly desired skill set.

KERN Precision is the U.S. division of KERN Microtechnik GmbH, which makes five-axis, high-precision micro machining centers for industries that use small parts with tight tolerances, such as aerospace, automotive, medical implants, and watch making. These machines are capable of drilling a hole in a human hair or even engraving it. In 2020, the company donated a KERN MMP micro machine center to Laney College in Oakland, Calif. for its Machine Technology Program.

Toni Mangold, president at KERN Precision Inc. in Addison, Illinois, noticed Laney College from its activity on Instagram, as part of a community using the “InstaMachinists” hashtag. The school and KERN shared an important goal — to build up the manufacturing workforce with skills in state-of-the-art processes.

“One of the major challenges our customers run into is finding the right people to run machinery,” Mangold says. “We’ve built these beautiful machines, but our customers struggle to find operators. We saw that Laney College had a wonderful program to teach young people to be machinists and get more people into manufacturing, so we wanted to support them.”

Learning many skills

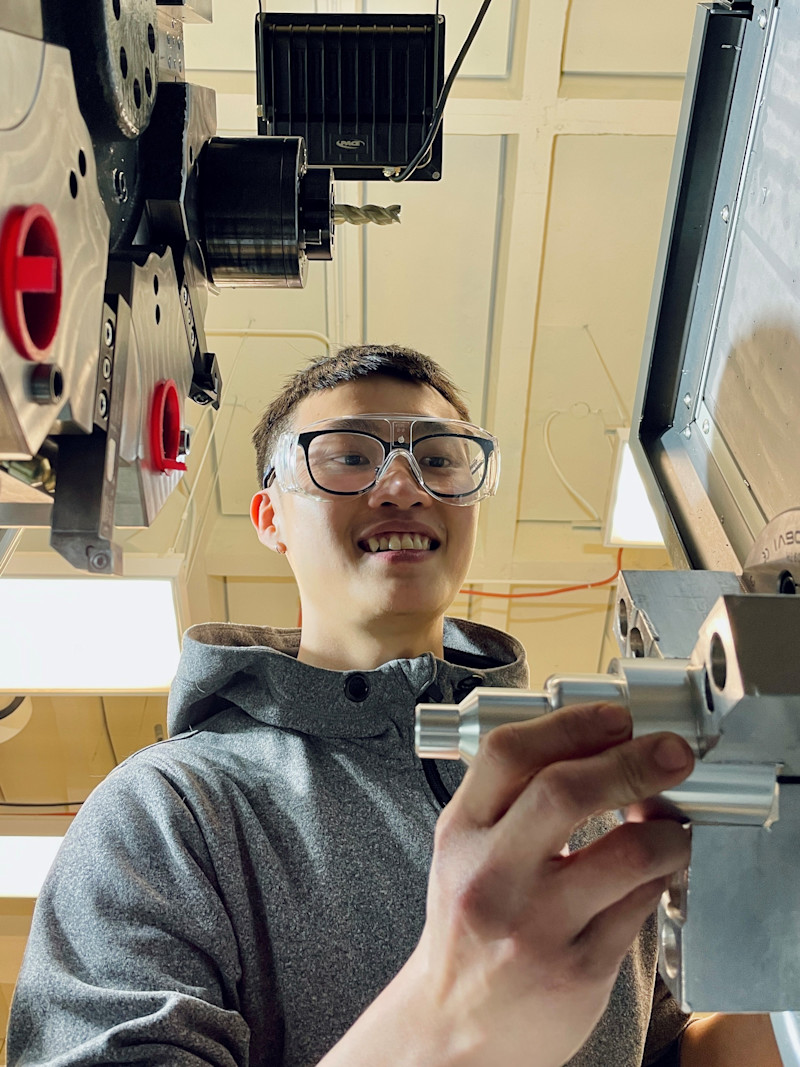

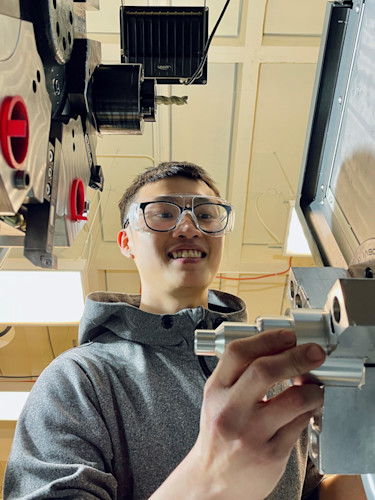

Students start with a foundational machine technology course that covers safety, blueprint reading, precision measurement, and manual machine tools. Subsequent courses cover gradually more advanced machining processes based on input from an industry advisory board.

“Our approach to the curriculum is to prepare people for the highest-level skills of the trade, and that means setting a very strong foundation. Then, they can learn anything, because they have that collective knowledge to pull from,” says Adam Balogh, instructor/chair, machine technology department at Laney College.

Over the years, the college has been under pressure to offer abbreviated, six-week training options because industry employers wanted workers immediately, but the school has remained steadfast in providing a more thorough, well-rounded education for its students.

“Some people just want warm bodies to push buttons, but that doesn’t serve students for the long term,” Balogh says. “Over time, we’ve won that argument with our industry partners. They’re realizing just how much skill and attention to detail these candidates really need.”

New high-precision machining course

Inspired by the acquisition of the KERN machine center, Laney College will begin offering a first-of-its-kind course in ultraprecision and micromachining in the 2023-2024 academic year. The course will cover advanced topics in machining and metrology for demanding applications requiring the highest precision and the smallest features. In addition to micro milling, students will learn about kinematic design principles, vacuum and adhesive workholding, diamond turning, and non-contact optical measurement methods, such as microscopy and interferometry. The new course is possible due to Laney College’s shop modernization project over the last decade, purchasing modern technology such as:

CNC machining centers with five-axis control, turning centers with live tooling

accessories like tilting rotary tables

a measuring microscope that performs onscreen measurement of micro parts

a 3D optical profiler that uses white light interferometry to make sub-nanometer measurements.

Success is personal As a graduate of Laney’s Machine Technology Program, Balogh knows first-hand how this education can be life-changing. While doing odd jobs and searching for a career in his 20s, Adam wandered into Laney’s machine shop, where instructors talked to him about the many opportunities in manufacturing. He signed up for a class, loved it right away, and eventually became a machinist. When Laney’s department chair was set to retire, Balogh knew he wanted to take that position.

“That program meant so much to me, my career, and my life. I’m raising a family with this trade,” Balogh says. “I wanted to help drive it to be successful and make sure it didn’t go away because a really successful program often depends on a single person who's pushing it, and if that person leaves and nobody's there to fill their role, then it'll just go by the wayside and it'll slowly atrophy and then get closed. And I didn't want to see that happen.”

Mangold, who started his career as a machining apprentice in Germany, knows the value of an industry/education collaboration.

“Technical education programs have a hard time surviving because of funding, machinery, and finding the right instructors,” Mangold says. “It's so important to get young people into these programs and offer them a career alternative. We don’t only need college grads and PhDs.”

For Laney College, expanding access to machining career opportunities does not stop there. Recent efforts to recruit female students have produced an 18% increase in female enrollment.

“If we really care about addressing the skilled labor shortage in manufacturing, we need to talk about encouraging women to enter the trade and making the trade a more welcoming place for them when they get here,” Balogh says.

Partnership for success

The relationship between KERN and Laney College is a great example of how industry and education can work together for the betterment of manufacturing.

“U.S. manufacturing is moving toward higher precision and smaller parts, and we’re trying to be on the cutting edge of that,” Balogh says. “I can’t overemphasize the impact that Kern’s donation continues to have on growing this program and its contribution to increasing the applicant pool of talented machinists out there.”

While donating equipment is important to supporting education, Toni offers advice to other manufacturing technology companies that want to help grow the workforce: “Offer apprenticeships and join advisory boards for your local colleges so they understand what they need to be teaching machinists to best meet industry demands today and tomorrow. We need more machinists, so it’s our responsibility to provide a future for these students.”

Check out LaneyMachineTech and KernPrecision on Instagram.

Contact AMT for more strategies on partnering with technical education providers in your region:

Catherine (Cat) Ross, Director of Smartforce Development, cross@amtonline.org.