What does it take to peer into deep space? The Giant Magellan Telescope is a $2.5-billion masterpiece that will be up to 200 times more powerful than today’s best telescopes. Among the Giant Magellan’s many advanced capabilities is hunting for habitable planets to determine whether molecules in the atmosphere are created by life — a capability that today’s telescopes are unable to measure in the visible spectrum because of a lack of sensitivity and resolution.

Sunlit daytime interior rendering of the Giant Magellan Telescope. Image credit: Giant Magellan Telescope – GMTO Corporation.

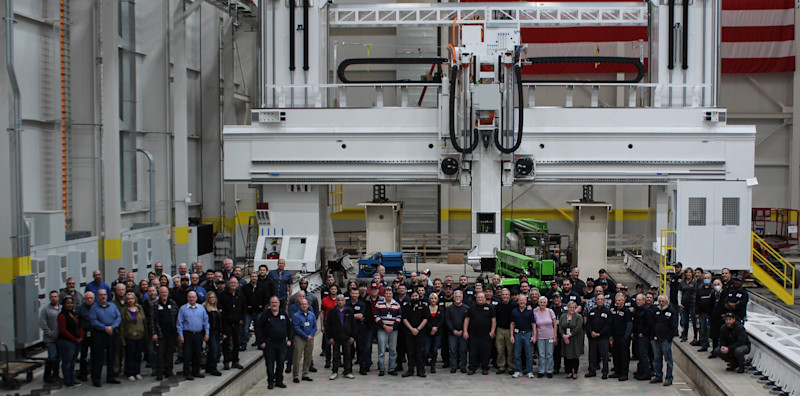

GMTO Corporation, the international non-profit organization responsible for the telescope, held a recent board of directors meeting at Ingersoll Machine Tools in Rockford, Illinois. Ingersoll was selected to machine the 127-ft.-tall telescope mount that will hold a primary mirror array consisting of seven of the world’s largest mirrors, each nearly 28 ft. in diameter.

“It’s one thing to deliver a capabilities presentation in an office. It’s quite another to say, ‘These are tools that we will use to make your telescope’ and demonstrate a MasterMill 5-axis vertical mill with the volumetric capacity for a school bus,” says Dr. Jeff Ahrstrom, Ingersoll CEO. “The board meeting here built confidence in us as manufacturing partner.”

Construction of the Ingersoll Machine Tools assembly hall for factory integration and acceptance testing of the Giant Magellan Telescope mount. Image credit: Ingersoll Machine Tools

The contract for the telescope mount is worth approximately $60 million over the life of the project.

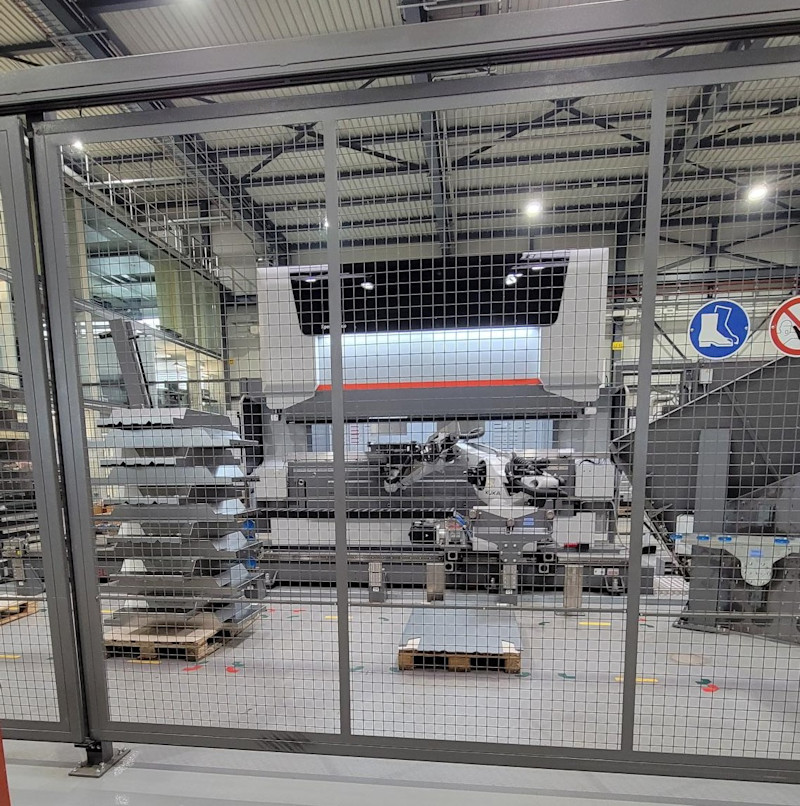

Massive Mill

Ingersoll is renowned for its large 5-axis milling machines, large additive manufacturing machines, and advanced fiber placement systems. In July 2022, Ingersoll held a grand opening and a 40,000-sq.-ft. expansion of its new manufacturing, assembly, and testing center, which includes a swimming pool-sized hole in the floor because the Giant Magellan Telescope mount would otherwise be too tall to fit under the ceiling.

The MasterMill destined for machining the telescope mount has a work volume of 25 by 11 by 6.2 meters and is the largest built by Ingersoll to date.

Cross section rendering of the Giant Magellan Telescope enclosure, pier, and mount. Image credit: Giant Magellan Telescope – GMTO Corporation.

“When we build a MasterMill, the cross rail has an accuracy measured in arc seconds,” says Ahrstrom. “To put that into perspective, the width of a dime placed two miles out from a point represents approximately two arc seconds. We bring that same level of precision to the telescope mount.”

During the GMTO Corporation board meeting, the directors had the opportunity to meet the people that built the MasterMill and will help machine the telescope mount.

“It's quite an experience to tour a manufacturing facility with some of the largest and most sophisticated machining tools in the world,” says Dr. Robert N. Shelton, president of the Giant Magellan Telescope. “The tour reminded me how massive the Giant Magellan Telescope will be and how critical Ingersoll Machine Tools is to our success. The people we met during the tour all have a remarkable breadth and depth to their talents. It’s clear that Ingersoll is the best place to build our telescope structure.”

“I could not have been more proud of our people,” says Ahrstrom. “Naturally we have engineers and people with advanced degrees, but our people on the shop floor are doing math and configuring motors and drives at a level beyond the skills of most college students. Whomever said manufacturing is dying never got to be part of building an amazing scientific instrument that will help us understand the origins of the universe.”

IMTS+ will continue to monitor this exciting project, as well as bring you updates on Ingersoll’s work to additively manufacturer the lunar habit[GU1] — featured in the AMT Emerging Technology Center at IMTS 2022 — that is part of NASA’s Artemis mission for deep space exploration.

"Our people on the shop floor are doing math and configuring motors and drives at a level beyond the skills of most college students. Whomever said manufacturing is dying never got to be part of building an amazing scientific instrument that will help us understand the origins of the universe."

– Dr. Jeff Ahrstrom, Ingersoll CEO

"It’s quite an experience to tour a manufacturing facility with some of the largest and most sophisticated machining tools in the world. The tour reminded me how massive the Giant Magellan Telescope will be and how critical Ingersoll Machine Tools is our success. It’s clear that Ingersoll is the best place to build our telescope structure."

– Dr. Robert N. Shelton, president of the Giant Magellan Telescope