“You must always have faith in people. And, most importantly, you must always have faith in yourself.”

– Elle Woods, "Legally Blonde"

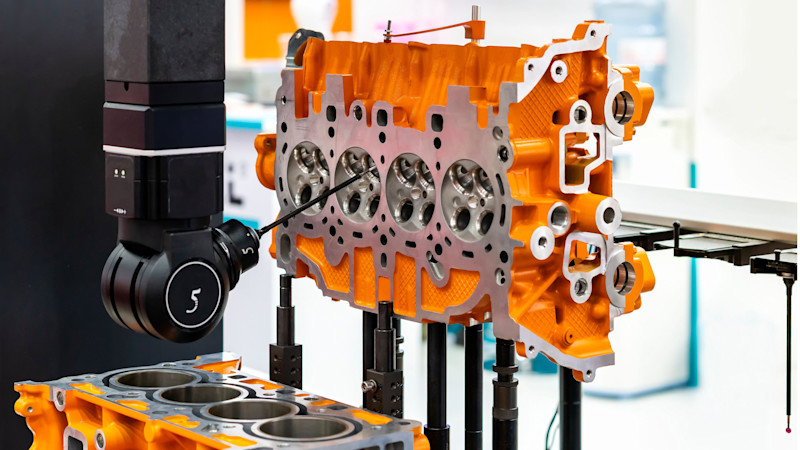

1. The Smart Evolution of CMMs

The coordinate measuring machine (CMM) has been an essential tool in the manufacturing industry since its invention in the 1950s. It has evolved over the years, with advances in computational power, 3D scanning, and multi-sensor capability, to help improve accuracy and efficiency in the measurement process. In the future, CMMs will be integrated with other advanced technologies, such as AI and the digital thread, to provide enhanced capabilities and improved efficiency.

2. US Navy Seeks To Modernize Maintenance

The U.S. Navy is looking for a partner to help them design, develop, and implement solutions for their equipment maintenance process that will allow operators to maintain equipment in the field without the help of highly trained technicians. The Navy would like to accomplish this by “using advanced prognostics via digital twins (DT) that identify problems to line replaceable units (LRU). This is especially applicable to ground combat platforms but is useful in all equipment.”

3. Heating Up

ABB is investing $20 million in its primary U.S. robot factory in Auburn Hills, Michigan, to meet the increasing demand for robots. This investment should help U.S. companies become more resilient by reducing supply chain issues, as well as making robots more attractive amid skilled labor shortages. The International Federation of Robotics estimates that the number of U.S. industrial robot installations will expand by 8% per year over the next three years, and ABB expects double-digit growth in the coming years.

4. Army Advanced Manufacturing

The U.S. Army has opened a new Advanced Manufacturing Commercialization Center (AMCC) in Sterling Heights, Michigan, to house the Army’s Jointless Hull subsection tool, a hybrid metal additive manufacturing machine used for engineering, development, and production in support of the full-size Jointless Hull machine located at Rock Island Arsenal. With the aim of improving Army readiness, the machine will have the capacity to build and machine much larger additively manufactured parts than currently possible.

5. If Balto Were a Drone …

Or Togo! I don’t want to anger any mushers out there. Anyway. Movie time! This week features a modern(ish) remake – sort of. While both Zipline (a company) and Balto (a dog) are known for delivering medical supplies, their approaches differed greatly. Zipline uses drone tech to deliver supplies to remote areas, while Balto delivered serum with sled dogs in a deadly Alaskan winter. That was also a one-time response to an emergency outbreak, whereas Zipline's service is an ongoing solution. Both are heroes of mine.

To get the latest tech developments delivered directly to your inbox, subscribe to the weekly Tech Report here.

To access Tech Trends, log in to or register for an MTInsight account at https://www.mtinsight.org/