“Everyone you meet is fighting a battle you know nothing about. Be. Kind. Always.”

– Robin Williams

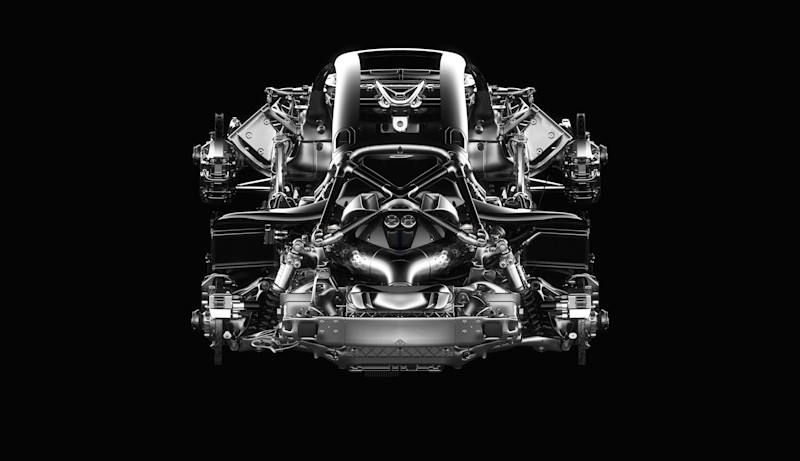

1. The 21C is Fast…

But can it win real races? Sure, lap times are cool, but two things make the 21C REALLY cool! Those two things boil down to the two types of people hyped about the 21C: #youpeople or my audience. People who know the state of the art in manufacturing are excited by this manufacturing masterpiece. The other type of person enthralled by the 21C is the motorsport nerd, those who know this car has the potential to be the next McLaren F1. But to be the next McLaren F1, you’ve got to dominate the French countryside at Le Mans, wheel to wheel against other cars, for 24 hours straight. My fingers are crossed that the 21C will eventually partake and really show the world how special it is.

2. “Sustainable” Invar Alloys

Yeah, I used the bad word! The Max Planck Institute for Sustainable Materials has a new method of producing Invar alloys without emitting CO2. These alloys are widely used in aerospace and precision instruments (like mechanical watch springs). The method integrates metal extraction, alloying, and thermomechanical treatment using hydrogen instead of carbon, saving energy and eliminating emissions. Challenges remain in scaling up, but the process promises a greener future for metallurgy… and maybe more ethical watches.

3. The Future of Computing

Prima Additive and Comau developed a 3D printing-based coating system for Stellantis' brake discs, reducing brake emissions by 80%. This solution, utilizing DED 3D printing, robotic arms, and laser systems, helps meet the EU's Euro 7 requirement of a 27% emission reduction by 2027. The process improves brake durability and sustainability. Stellantis will deploy the system at its Septfonds, France plant in late 2024. Welp, this validates Porsche’s work from more than half a decade ago!

4. Biting the Dust

I like Spot, but I’m still a bit pessimistic about its viability on the factory floor. But I may have to reassess my position: The quadruped AMR – already incredibly flexible and able to be applied to unstructured environments – can now open doors. This may seem like a small thing, but the use case of a machine adapting to its environment is a sound one for large structures that probably won’t change much in the next century.

5. “We Own the Night”

The University of Michigan has developed a thin, lightweight OLED device that could replace bulky night vision goggles. This new technology converts near-infrared light into visible light and amplifies it over 100 times without the heavy, high-voltage components used in traditional phosphorus image-intensifying tubes (IITs). The device consumes less power, extends battery life, and exhibits memory behavior, making it potentially useful for computer vision and neuromorphic applications. I asked a friend who works for a certain IIT manufacturer to confirm the legitimacy of this article. They reported back that the new tech achieves a ≥3,600 FOM (figure of merit). The current US military specification is ≥2,600 FOM. “Yeah, this is legit.”

To get the latest tech developments delivered directly to your inbox, subscribe to the weekly Tech Report here.

To access Tech Trends, log in to or register for an MTInsight account at https://www.mtinsight.org/