"Abandoning today's commodity manufacturing can lock you out of tomorrow's emerging industry."

– Andy Grove, Intel’s former CEO (1987-1998) and chairman (1997-2005)

This is a published version of the AMT Tech Report newsletter. You can sign up to get the Tech Report in your inbox here.

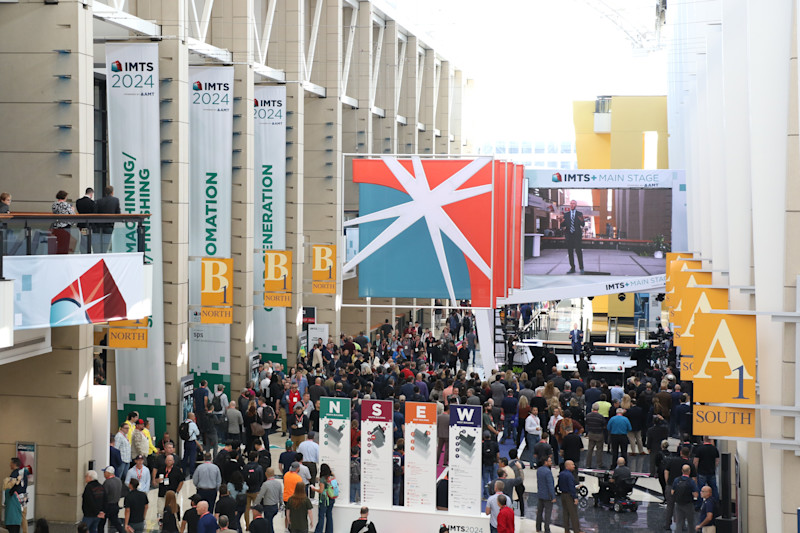

1. IMTS 2026: Manufacturing’s Biggest Stage

Registration is now open for IMTS 2026, running Sept. 14-19 at Chicago’s McCormick Place. The show promises to be a global hub for everything from machine tools and metrology to AI, additive, and automation, giving shops of all sizes a chance to “Achieve the Impossible.” With reshoring momentum, fresh tech demos, and real-world case studies, it’s shaping up to be the manufacturing event no one wants to miss.

2. Nvidia and OpenAI’s $100B Play

Nvidia plans to invest up to $100 billion in OpenAI and supply it with data center chips. The move links the two AI powerhouses: OpenAI gains capital and compute to keep pace in the model arms race, and Nvidia secures a customer and deeper integration. The deal could reshape the AI supply chain, deploying 10 GW of Nvidia systems by 2026, enough juice to power millions of U.S. homes, and cement Nvidia’s role at the core of AI infrastructure.

3. Print It, Then Cut It

Zero Tolerance makes the case that 3D printers belong in mold shops. They started with desktop polymers for fixtures and end-of-arm tooling, added carbon fiber parts, and now run a stainless LPBF machine from Xact Metal to print cavity and core inserts with conformal cooling circuits. A printed jig saved them 25 seconds on their cycle time and doubled daily output. They print a part, machine/EDM it, tie fixtures into the CMM, and move prints onto a gantry robot. Cheaper mistakes, faster iterations, better uptime.

4. X-37B Aims Its Lasers at the Future

NASA and the U.S. Space Force are sending the X-37B spaceplane on its eighth mission to test laser communications and quantum inertial sensors, technologies that could redefine secure satellite links and GPS-free navigation. With a billion-dollar budget and years of orbital endurance, the platform will stress test high-speed data links and next-gen sensors to push space operations closer to science fiction.

5. Fives Adds Muscle With Pietro Carnaghi

French industrial group Fives has acquired Italian machine-tool builder Pietro Carnaghi, folding its giant lathes, gantry mills, and flexible manufacturing systems into Fives’ High Precision Machines division. The combined unit spans 24 entities worldwide, expects to generate 400-450 million euros in annual revenue, and includes a 45,000-square-meter plant in northern Italy. This gives Fives more capacity for large, complex parts in aerospace, energy, and defense.

To get the latest tech developments delivered directly to your inbox, subscribe to the weekly Tech Report here.

To hear the latest in additive manufacturing, material removal, automation, and digital manufacturing, subscribe to the AMT Tech Trends podcast here.