"There is no such thing as a boring project. There are only boring executions."

– Irene Etzkorn, Chief Clarity Officer, Siegelvision

This is a published version of the AMT Tech Report newsletter. You can sign up to get the Tech Report in your inbox here.

1. Robots Keep Marching

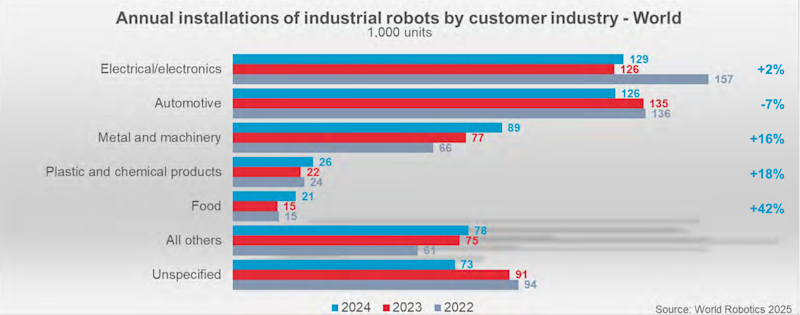

Global robot demand hasn’t slowed! In 2024, 542,000 units were installed globally – more than double the number installed a decade ago. Manufacturing (metal and machinery) showed steady gains, while service robots (including AMRs) grew about 10%. Medical robots popped off, growing 91% in 2024. Asia continues to lead industrial installs, but across sectors, the trend is clear: Robots aren’t replacing labor; they’re multiplying capability.

2. Dreamliner’s Secret Sauce

Boeing’s 787 Dreamliner earns its fuel-sipping reputation through composites that cut weight, wings designed for cruise efficiency, and next-generation engines that squeeze out more thrust per pound of fuel. Add in flexible variants (787-8, -9, -10) and a fly-by-wire system architecture, and airlines get a family of aircraft that opens new routes, reduces costs, and boosts comfort – all while burning roughly 20%-25% less fuel than older widebodies.

3. Hitachi Builds Its Own AI Foundry

Hitachi is setting up a global AI factory using Nvidia’s reference architecture, complete with Blackwell GPUs, Spectrum-X networking, and Omniverse tools. The system will unify compute resources across the United States, Europe, the Middle East, Africa, and Japan, letting engineers build and deploy physical AI models for sectors such as energy, mobility, and industrial technology. It’s part of Hitachi’s Lumada 3.0 push to transform data into real-world efficiency and next-gen digital twins.

4. When ‘Overbuying’ Pays Off

Marathon Precision just scored a 2025 Top Shops Award – not for one trick, but for a string of smart choices: vertical integration, investing in tech before demand spikes, and a shop culture that doubles as an art studio and garage. With everything from palletized CNCs to blacksmithing under one roof, they keep complex, high-tolerance work in-house while boosting employee skills. As it turns out, “overbuying” machines and trusting your people is a pretty solid business plan.

5. Grinding Errors Down to Size

Face gear grinding isn’t exactly forgiving; thermal and geometric errors can quickly trash any hope of precision. Researchers developed a real-time compensation framework using a Taylor-GCN/M-LSTM model to capture heat effects and introduced a sensitivity analysis method to rank error sources. The closed-loop system responds in under 65 milliseconds and cuts tooth flank errors by 63.4%. In plain English: Smarter math plus feedback equals gears that fit right the first time.

To get the latest tech developments delivered directly to your inbox, subscribe to the weekly Tech Report here.

To hear the latest in additive manufacturing, material removal, automation, and digital manufacturing, subscribe to the AMT Tech Trends podcast here.