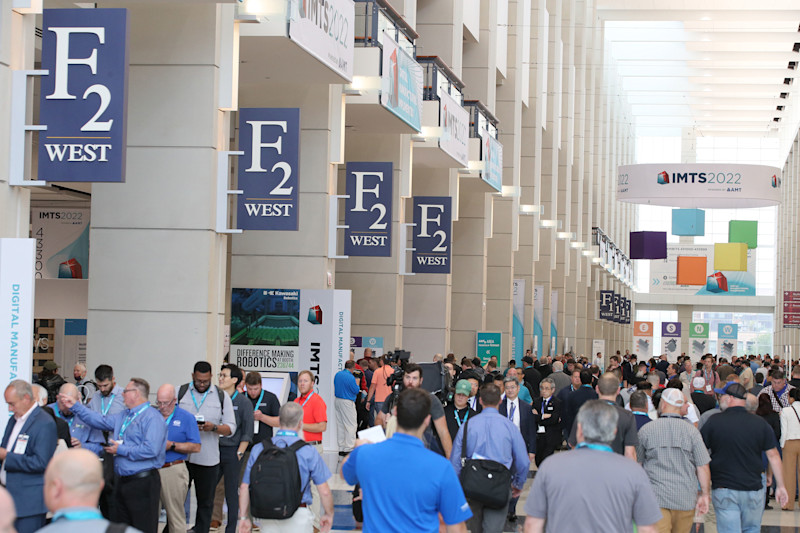

Over the past few years, global supply chain disruption has caused manufacturers to seek better ways to source parts and distribute products. A tighter connection between manufacturing and supply chain technologies can reduce inefficiencies, delays, and other operational challenges to increase performance and profitability. Professionals from many facets of the supply chain will gather to share practical strategies for better process integration at the IMTS 2024 Supply Chain Forum, held Wednesday, September 11, 10 a.m.- 4p.m. at Chicago’s McCormick Place. Register here to attend. The day-long event is presented by AMT – The Association for Manufacturing Technology, the Council of Supply Chain Management Professionals (CSCMP), and Agile Business Media & Events. The forum is a full day of live demonstrations, expert panel discussions, presentations from industry leaders, and a networking lunch — all addressing solutions to unite upstream manufacturing technologies and downstream supply chain capabilities. Discussions will cover hot industry topics, such as additive manufacturing and automation to streamline the supply chain, opportunities in the reshoring movement, and digital transformation. “We need to be aware of a potentially growing chasm between manufacturing and supply chain innovations as technology evolves and gets implemented, which can result in new risks and inefficiencies,” says Tony Poidomani, senior vice president of business development at Agile Business Media and Events .”Alternatively, transparency and shared data analytics could combine best practices between upstream and downstream processes.” For example, Poidomani states that changes in product design, consumer behaviors, and packaging can impact warehousing and transportation. When it’s all connected in a closed loop system, it optimizes the entire process and ultimately delivers a better customer experience. High-impact presentations and panel discussions at the IMTS Supply Chain Forum include:

Revolutionizing The Global Furniture Supply Chain: Haddy's Advanced 3D-Printing Robotics, presented by Jay Rogers, co-founder and CEO at Haddy

Automation ROI: Solving the Top 3 Operational Challenges, presented by Spiros Tzanetakos, senior regional manager at Bastian Solutions

Reshoring is Surging. How OEMs, Job Shops and Technology Suppliers Can Benefit, presented by Harry Moser, founder & president at Reshoring Initiative

Equipping the Factories of the Future, presented by Will Drewery, founder and CEO at Diagon

The Rise of the Connected Factory: Charting Manufacturing’s Digital Transformation, presented by Enrique Herrera, industry principal - manufacturing at Zebra Technologies

Democratize Engineering and Supply Chain Data, presented by Chris Brown, vice president of sales at CADDi

To uncover solutions for a more efficient manufacturing supply chain, register for the IMTS Supply Chain Forum, Sept. 11, at https://www.imts.com/show/education/SupplyChainForum.cfm.