For the most part, engineers and manufacturers focus on developing and producing things in a way that falls within the definition of “continuous improvement.”

That is, they analyze the product being produced and look for ways to enhance it. Perhaps this means changing a feature or deploying a new material. But regardless of how the upgrade is achieved, it is still the same product, just upgraded.

Similarly, people tend to make incremental improvements on the manufacturing floor, such as tweaking feeds and speeds in machining operations or reconfiguring layouts to minimize material handling. These are cases where existing processes are essentially augmented.

Kaizen Works

Regardless of what is being manufactured, in recent years, companies have turned to the Toyota Production System, a philosophy built around the core principle of “kaizen,” which is Japanese for “continuous improvement.” Industries in the United States have paid keen attention to the Toyota Production System since 1990, when MIT published “The Machine That Changed the World,” a pioneering text that explores the automotive industry and Toyota’s lean production principles in action. Year after year, Toyota makes changes to its products and in its plants. And it works.

In 2024, the Toyota RAV4 had sales of 475,193 in the United States, becoming the country’s bestselling vehicle and surpassing the Ford F-150, which had held the top spot for 42 years running. Clearly, this is an example, in part, of the continuous, incremental improvement approach.

The Toyota Camry has been the bestselling passenger car in the United States for 23 consecutive years, arguably taking its competition from Ford, GM, and Stellantis out of the segment.

And while the Detroit Three have turned their attention away from passenger cars to focus on trucks and SUVs, the Toyota Tacoma has been the top-selling small pickup for 20 consecutive years, and the aforementioned RAV4 was the bestselling SUV for eight years in a row.

In the J.D. Power 2025 U.S. Vehicle Dependability Study, which looks at vehicles after three years of ownership, which is arguably a metric of quality (although in auto parlance it is considered “dependability” or “reliability”), Toyota’s Lexus is the leading brand; Toyota has six model-level awards, and the Toyota Avalon is the top overall model in the study.

This is not to brag about Toyota but to make the point that the Toyota Production System gets results.

Significant results.

Today, Toyota is the top vehicle manufacturer in the world in terms of volume. It produced 10.4 million vehicles in 2024, besting Volkswagen Group’s 8.4 million, or about 24% more.

But You Need To Go Beyond Kaizen

However, unless something black swan in nature occurs between when this is written and when you read this, Toyota isn’t the most valuable vehicle manufacturer in the world. Not by a long shot.

That market cap leader is Tesla, which surpassed Toyota in July 2020 and hasn’t looked back.

So, is Toyota’s continuous improvement approach being eclipsed by Tesla’s strategy of disruptive improvement?

Just as “The Machine That Changed the World” caused companies to reconsider their processes, Clayton Christensen’s “The Innovator’s Dilemma” made companies rethink their product development practices.

Christensen pointed out that companies tend to focus on “sustaining innovation.” This is fundamentally continuous improvement, tweaking and adjusting the product and the process, but essentially doing the same thing in the same way it has always been done.

It causes a company to think, “So, why change?”

Disruption Isn’t Smooth

One of the examples Christensen uses in the book is the disk drive industry.

A few of you will remember the 8-inch floppy disk. It was introduced in 1971 and was followed by the 5.25-inch floppy disk in 1976, the black, flexible disk you slotted into your desktop PC that ran MS-DOS. (In 1982 the 3.25-inch disk was introduced, which had a rigid plastic case, but that is post-“Dilemma.”)

Christensen points out that the floppy disk manufacturers were good at producing disks, had high technical competency, and were making money from this approach.

Why would they change?

The thing about disruptive innovation is that the disruptive product typically underperforms existing technology, which doesn’t make a whole lot of sense. However, it is also generally simpler and less expensive than established products, and it may address a market niche.

Said another way: If you continually improve a product, the transitions are comparatively smooth. But if you take a disruptive approach, things are jarring – but very well may address a new or growing market demand.

When was the last time you saw an 8-inch floppy disk? When did you last buy a computer with a disk drive? These days, you’re lucky if you find a USB-C port.

This brings us back to Tesla.

The powertrain of a Model 3 has fewer parts by several orders of magnitude than the internal combustion engine in a Toyota Camry (which is now hybrid-only, so you have to add in that system, too). So, it is simpler. And while it is more expensive (starting around $42,500 versus $28,700), from a utility point of view, it underperforms: The top range of a Model 3 is 363 miles compared to a Camry’s 663.

But Tesla is completely changing how vehicles are designed, engineered, and produced, something that other global automakers – including Toyota – are following. The reason: the ability to improve profit margins by reducing manufacturing costs.

And these changes apply to the production of any product, though not necessarily on a one-to-one basis: Adaptation to conditions is required.

What Are You Trying To Accomplish?

One of Tesla’s advantages – which might have seemed like a disadvantage – was that the company hadn’t made cars before. Change is challenging, and Tesla didn’t have decades of legacy that would feed into “we’ve always done it this way” thinking.

Instead, the thinking used by Tesla is based on “first principles.”

This essentially means you figure out what you are trying to accomplish and then use the simplest method to do it.

One thing Tesla has revolutionized is building the structure of a vehicle (although there are vehicle manufacturers in China that have been doing this, too – and again, because these Chinese companies are generally new, they aren’t restricted in their approach by existing equipment and policies). Conventionally, many parts are stamped and welded (or otherwise fastened) to create a vehicle’s rear structure. Tesla engineers looked at the Model 3 and saw 171 parts in the front and rear structure. Making and assembling all those individual pieces is highly complex, from the tooling to the machinery to the logistics. Tesla decided to take an entirely different approach for the Model Y: “gigacasting.”

They cast the components with a machine that can move some 100 kg of molten aluminum into a die cavity in roughly 100 milliseconds and then applied over 6,000 tons of pressure. The 171 parts became two.

Gigacasting is now used for other vehicles’ front and rear structures.

(This has implications for equipment providers for companies like Telsa, ranging from suppliers of welding robots to those of metal-removal equipment. According to manufacturing expert Sandy Munro, CEO of Munro & Associates, for example, “the front Cybertruck casting has about 30 holes – top, bottom, and sides. All are square to each other, and most are cast holes.” He adds, “The amount of machining is minimal and consists mostly of drilling and spot-facing. Some of the tapped inserts are self-tapping directly into the cast holes.”)

The point is not about the benefits of gigacasting.

Rather, this is about looking at what is to be accomplished and how it might be done in a profoundly different way.

The Assembly Line Works. But After 100 Years…

Which brings us to a second change Tesla is making to the way vehicles are manufactured: “unboxed assembly.”

You may be more familiar with this in the context of a “modular build.” In a traditional moving assembly line, a vehicle structure is built up sequentially, piece by piece (a “box” is built – think body-in-white – and then more parts are added). In the unboxed assembly approach, large subassemblies are simultaneously manufactured and then integrated. The classic assembly line is replaced by automatic guided vehicles.

Consequently, the size of an assembly plant can be reduced by as much as 40%. This is not just a savings of bricks and mortar but all other costs associated with a facility, from energy to insurance.

According to Mathew Vachaparampil, CEO of Caresoft Global, an engineering and automotive benchmarking company, Chinese and European automotive companies are developing unboxed operations to achieve significant savings.

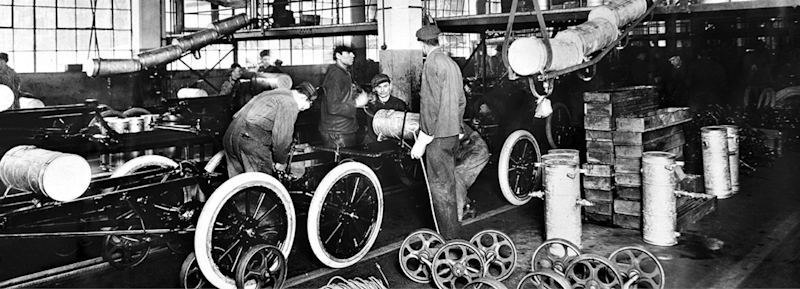

While some people who don’t manufacture cars might think this isn’t relevant to them, they must consider: (1) It very well may be relevant if what is being manufactured requires the assembly of other elements (although a redesign may be required to perform a modular build efficiently); and (2) Henry Ford installed his first moving assembly line in 1913 – isn’t it likely that incremental improvements have run their course, and a disruptive approach is necessary?

It is reasonable to think that what you’re making now – and how you’re making it – is keeping the lights on and sustaining your business. Gigacasting and unboxed assembly may be interesting, but they don’t fit into what is presently paying the bills.

Still, some are doing things differently, which may undercut what you are doing, and the market you are serving may slowly (or quickly) cease to exist.

Do It Differently

How can you address this?

Consider an approach from 1943. Lockheed was a supplier of aircraft to the military that did things in a traditional way. The Air Tactical Service Command (ATSC) came to Lockheed and said it wanted a jet fighter developed in 180 days. Given that it ordinarily took years to deliver a prototype, not a handful of months, imagine what the folks at Lockheed must have thought when the guys from ATSC left the room.

Instead of laughing it off (or taking the contract and then operating business as usual), they formed a new division: Skunk Works. Under aeronautical engineer Kelly Johnson, Skunk Works was a small team comprised of fewer than 30 engineers who worked independently from Lockheed’s main operations. They delivered the XP-80 prototype – which was to become the P-80 Shooting Star – in 143 days, 37 days faster than their allotted time.

How did they do it? One key factor was codifying 14 rules for fast, innovative, and efficient product development, including: “The number of people having any connection with the project must be restricted in an almost vicious manner. Use a small number of good people (10% to 25% compared to the so-called normal systems).” If Lockheed had put the ATSC job in the hands of the traditional product development team rather than creating this new group, that assignment would have eventually been fulfilled, but …

Creating your own independent group that can apply “first principles” thinking may give you a competitive advantage that continuous improvement cannot.

If you have any questions about this information, please contact Gary at vasilash@gmail.com.

To read the rest of the Emerging Markets Issue of MT Magazine, click here.