When a business model works for a century, it’s due to a combination of the strength of its core principles and its ability to adapt to economic, technological, and cultural changes to maintain relevance across multiple generations. One such model is using distributors to connect manufacturing technology buyers with builders, which began with the creation of the American Machine Tool Distributors Association (AMTDA) in 1925. AMTDA merged with AMT – The Association For Manufacturing Technology in 2012, and AMT is now the steward of this 100-year-old tradition.

To help distributors continue to operate at peak efficiency, AMT has organized the 2025 Distribution Summit (D25), which will be held Nov. 18-19 in Carmel, Indiana. The meeting will offer educational sessions and networking opportunities designed to address the unique needs of manufacturing technology (MT) distributors.

“D25 is the only meeting in the United States programmed specifically for manufacturing technology distributors and sales training,” says Douglas K. Woods, president of AMT. “As our fourth ‘D’ meeting, D25 reflects our long commitment to supporting distributors, which has continued since the AMTDA/AMT merger. We anticipate about 150 people will attend, including distributors, builder representatives, expert speakers, and AMT staff.”

The agenda features four key learning sessions for attendees to learn what to say, how to say it, whom to say it to, and how to master sales:

How To Use AI Sales Roleplay and Coaching To Build Sales Confidence, Capability, and Consistency

Session leader: Matt Conway, senior sales executive, Second Nature

Likeability Is Personable Communication

Session leader: Bill Graham, president, Graham Corporate Communications

Harnessing Data for More Efficient Sales Targeting

Session leader: Kevin Bowers, vice president – research, AMT

The Path to Sales Mastery

Session leader: Jeff Radichel, CEO, The Next Step

Following the presentations, the speakers will hold breakout sessions to drill deeper into their topics and respond to distributor questions. The agenda also includes looking back at AMTDA’s history and plenty of networking opportunities.

“The nature of distribution makes it prone to inefficiencies because you are trying to identify sales targets, establish new relationships, and build trust – all of that takes time,” says Brooke Sykes Jr., CMTSE, president and owner of Cardinal Machinery. “D25 gives people the knowledge that can help them create more success in the same amount of time.”

Distributors are part of a local community’s fabric, such as when Cardinal Machinery and builder Smart Machine Tool sponsored the entry of pitmaster and customer Ron Monmaney Jr. (second from left), owner Mitchell and Son Inc., at the 2025 World Championship Barbecue Cooking Contest.

“There’s nothing more valuable than networking with your peers,” adds Willie Eichele, president of distributor The HEH Group and a member of AMT’s board of directors. “Having a conversation over dinner, coffee, or in a breakout session is where you get sound advice, such as ways to manage an employee or navigate a builder contract. D25 creates a space where you can take yourself out of sales gear and put your mind in neutral so it can absorb new information.”

In addition to cross-pollinating and sharing ideas, networking helps people recharge their mental batteries. Salespeople have a lot of tough conversations. Connecting with others who have shared experiences helps distributors remember that hearing “no” isn’t personal rejection but just part of the job.

100 Years of Distribution

D25 will also recognize the extraordinary success of the distribution business model. A customer’s trust in a business grows from localized efforts, and distributors provide the crucial elements of local trust, attention, and technical expertise.

“The value of distribution is that we are the feet on the street and your trusted friend,” says Brad Haas, president and engineer at KOMT (Kansas Oklahoma Machine Tool). “Our sales engineers don’t just work alongside the manufacturing engineers and facility owner. Our kids play ball with each other, we go to the same churches, and we shop at the same supermarkets. When a customer asks our sales engineers for a machine recommendation, they know we will support that recommendation throughout the machine’s life-cycle.”

Distributors create something powerful by forming a seamless relationship between the local customer and the remote builder. For example, Sykes remembers a situation where a builder could not meet its promised delivery date, but the customer had already hired an operator for the machine. Instead of that relationship going sideways, Cardinal Machinery helped negotiate factory technical training and a smaller, loaned machine to upskill the operator in the interim before delivery.

“There’s no way a remote builder or somebody coming in and out of a territory every quarter can establish that type of rapport or cohesion,” comments Eichele, who is proud of how distributors add value to the manufacturing industry.

The distribution business model has worked for 100 years due to its founding principles.

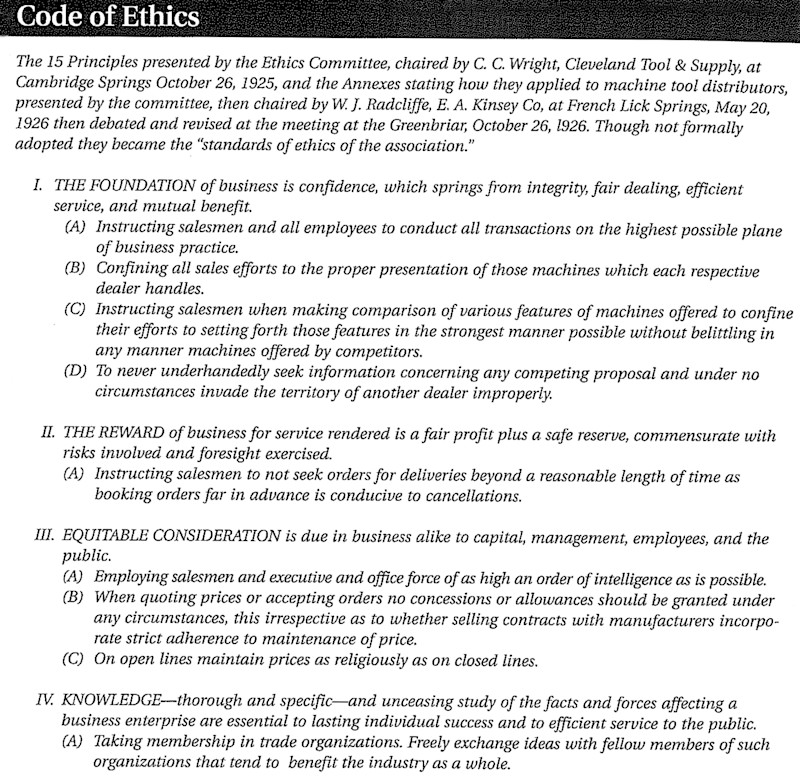

“I was looking at the AMTDA code of ethics, which was introduced on Oct. 26, 1925,” Eichele continues. “Originally written 100 years ago, the first of its 15 principles states, ‘The foundation of business is confidence, which springs from integrity, fair dealing, efficient service, and mutual benefit.’ It’s incredible how pertinent and important these principles are today.”

Eichele can directly trace the origins of his firm, Motch & Eichele, to AMTDA. AMTDA’s first chairman was George Merryweather of the Motch & Merryweather Machinery Co. of Cleveland, Ohio. Merryweather’s business partner was Edwin Motch II, the father of one of the founders of Motch & Eichele.

“In 1985, Edwin Motch III became my father’s business partner in founding the Motch & Eichele Co., which is today one component of The HEH Group. I continue to be amazed and humbled by the history of our industry,” says Eichele, who leads both Motch & Eichele and The HEH Group.

Registration is now open for the D25 Summit, which will be held Nov. 18-19 in Carmel, Indiana. Visit AMT Online to register and explore unique sponsorship opportunities to promote your brand to the most influential manufacturing technology sales network in the United States.