In an effort to close the manufacturing skills gap, forward-thinking schools are engaging young people by combining passionate teachers with a strong advanced manufacturing curriculum and a cyber-physical learning environment. That formula was the basis for a three-day mechatronics competition at the Smartforce Student Summit at IMTS 2022.

The Space Coast Consortium Apprenticeship Program (SCCAP) and Festo Didactic North America kicked off the first-ever live SCCAP/Festo Mechatronics Competition, culminating in an award ceremony to recognize winners Carolyn MacGowan and Kate Borelli, third-year SCCAP apprentices and employees at Airbus OneWeb Satellites. MacGowan and Borelli’s achievement is especially significant in the context of the male dominated field of advanced manufacturing and reinforces the importance of our industry’s appeal to all people, particularly Generation Z who possess the digital aptitude and desire for these exciting, high-tech careers.

“When we told friends about the competition, they immediately said, ‘Oh, I’m so jealous you get to go to IMTS,’” says Borrelli. “It was definitely mind boggling to realize how big this competition would be.”MacGowan’s tip for young girls on the fence about whether to pursue a STEM career: “Don't be afraid to try new things and take a little bit of a risk, and don't give into peer pressure about what you like and dislike. There's more to STEM than just engineering. There's a lot more out there than you think.”

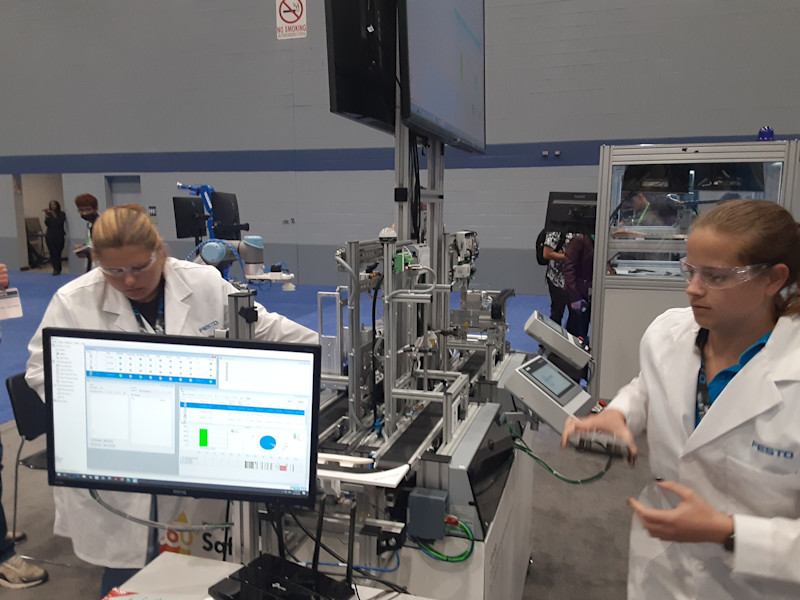

Photo caption: Katie Borrelli and Carolyn McGowen, employees at Airbus OneWeb Satellites, talk about their experience at the Space Coast Consortium/Festo Mechatronics Apprentice Competition, held recently at the IMTS 2022 Smartforce Student Summit. They share the challenges of the 3-day cyber-physical competition, the exhilaration of winning first place, and the importance of having more women in STEM careers. (edited)

SCCAP, an industry-led, State of Florida-registered apprenticeship program for advanced manufacturing, has partnered for years with Festo Didactic, a world-leading provider of equipment and solutions for technical education. SCCAP first executed a machinist apprentice competition at the Smartforce Student Summit at IMTS 2018. Working with AMT – The Association For Manufacturing Technology, the owner and operator of IMTS,SCCAP committed to an even bigger and better display at IMTS 2022 with Festo Didactic as its mechatronics partner.

“A great majority of the open positions in jobs in manufacturing are in the mechatronics area, which is why it’s critical that we focus on it,” Greg Jones, AMT’s vice president of Smartforce Workforce Development, says. “The competition demonstrated the classroom of the future. We hope to see classroom program labs using this kind of equipment, and we need more companies to invest in this technology for their own on-the-job training.”

Mechatronics skills are highly sought after today for engineering, design, and technician jobs in robotics, automation, and controls.

Teaching the right lessons SCAAP has been using Festo technology in its mechatronics apprentice curriculum and lab exercises for three years.

“To make sure our competition had everything, we needed to apply the right lab tasks and academic theory. We knew Festo was the right partner for the job,” Bryan Kamm, SCCAP founder, says.

To ensure the competition’s content was understandable and implementable, Festo brought in Stefany Gurgel, applied mechanical engineering teacher at Monmouth County Vocational School District in Tinton Falls, N.J.

“I worked shoulder to shoulder with the Festo Solution Center Engineering team in making sure that the project-based curriculum was written to hold the students’ attention and inspire teachers,” Gurgel says.

Three-Day Competition Based on Skill Building The competition was broken down into building blocks to ensure success for each apprentice. Every day included new theories and skills that are essential for mechatronics careers.

On day one, the four competing teams learned about individual areas of mechatronics and worked on two different systems. One was a conveyor system that sorted plastic and metal pieces. The second was a magazine station where a pneumatic cylinder would place and hold a lid onto a container.

On the second day, participants used Festo’s Industry Learning System I4.0, a cyber-physical learning platform that includes a project workstation, lab, and factory, each with modules and pallets to simulate different layouts. The two stations of mechatronics learned the previous day were combined into one. Starting at the conveyor station, the plastic pieces would move on to the magazine station while the metal pieces were sorted out. They also got to troubleshoot a handling station in which they worked with pneumatic components, electrical sensors, and simulation software.

The final day focused on robotics and understanding the use of safety sensors when doing a risk assessment. Throughout the competition, the students used augmented reality features by downloading a Festo app that provides access to data sheets for all components, which helped create a rich data experience on the troubleshooting journey.

“From my perspective as a teacher, when you teach students a concept, if you can tie it to a physical skill and incorporate hints in a digital form to their personal mobile devices, they learn it a lot quicker. They're more interested and engaged, so we brought that to the competition,” Gurgel says. “When you extend theory too long without doing something, you tend to lose students. We did a little bit of theory and then put them on a hands-on skill.”

Scoring was done based on where students could complete the assigned tasks. Every task had a specific set of points. If a student was not able to complete a task, they would get no points and receive help with learning it so they could proceed to the next step.

Spotlight on mechatronics The competition was a spectacle for everyone to witness, giving student attendees a chance to see what mechatronics is all about.

“We need more passionate technical educators and better awareness of advanced manufacturing,” Gurgel says. “Parents and students need to know all these different areas where they can pursue a career. You don’t always have to go through a four-year college, and there are so many opportunities in the manufacturing world. That’s why the Student Summit was my favorite place at IMTS 2022.”

Festo hopes a program like this is scalable to apply widely to high schools and technical colleges.

“We need to close the skills gap, and to do that, we need strong instructors and strong content for them to teach,” Ted Rozier, director of engineering for Festo, says. “This competition allowed us to take Stefany’s amazing teaching ability and match it with true Industry 4.0 competencies that are tightly integrated into our curriculum. It clearly showed us that if we use I4.0 CORE curriculum to complement our cyber-physical training system in any education facility, teachers and students will rise to the occasion very quickly.”

As each day went along, more and more companies at IMTS were visiting the competition and showing interest in participating in this type of event in the future. At IMTS 2024, AMT, SCAAP, and Festo promise an even more advanced apprentice competition. Expect great things at the Smartforce Student Summit in September 2024.