The supply chain was broken, people and 3D printing rose to the occasion

Many have been asking what the implications of the current COVID-19 pandemic are going to be on additive manufacturing as an industry. The relationship between coronavirus and 3D printing is not entirely clear, mostly because we are very far from understanding what the long, medium and even short terms implications of the pandemic are going to be on global supply chains.

Additive manufacturing may be able to play a role in helping to support industrial supply chains that are affected by limitations on traditional production and imports. One thing is for sure though: 3D printing can have an immediate beneficial effect when the supply chain is completely broken. That was, fortunately, the case when a Northern Italian hospital needed a replacement valve for a reanimation device and the supplier had run out with no way to get more in a short time.

One of the biggest immediate problems that coronavirus is causing is the massive number of people who require intensive care and oxygenation in order to live through the infection long enough for their antibodies to fight it. This means that the only way to save lives at this point – beyond prevention – is to have as many working reanimation machines as possible. And when they break down, maybe 3D printing can help.

Massimo Temporelli, founder of The FabLab in Milan and a very active and popular promoter of Industry 4.0 and 3D printing in Italy, reported early on Friday 13th that he was contacted by Nunzia Vallini, editor of the Giornale di Brescia, with whom he has been collaborating for several years for the dissemination of Industry 4.0 culture in schools.

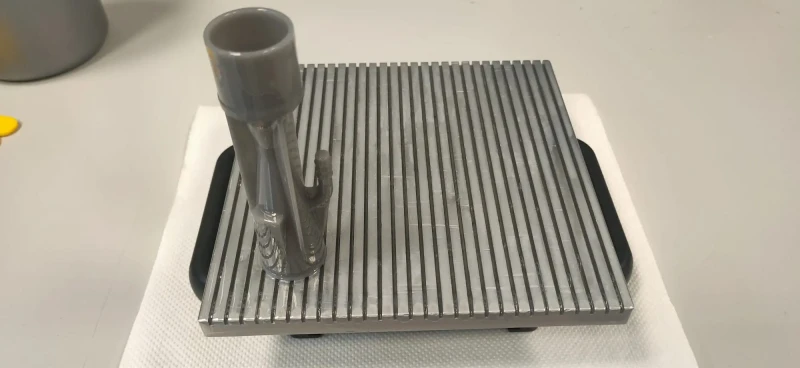

She explained that the hospital in Brescia (near one of the hardest-hit regions for coronavirus infections) urgently needed valves (in the photo) for an intensive care device and that the supplier could not provide them in a short time. Running out of the valves would have been dramatic and some people might have lost their lives. So she asked if it would be possible to 3D print them.

After several phone calls to fablabs and companies in Milan and Brescia and then, fortunately, a company in the area, Isinnova, responded to this call for help through its Founder & CEO Cristian Fracassi, who brought a 3D printer directly to the hospital and, in just a few hours, redesigned and then produced the missing piece.

On the evening of Saturday 14th (the next day) Massimo reported that “the system works”. At the time of writing, 10 patients are accompanied in breathing by a machine that uses a 3D printed valve. As the virus inevitably continues to spread worldwide and breaks supply chains, 3D printers – through people’s ingenuity and design abilities – can definitely lend a helping hand. Or valve, or protective gear, or masks, or anything you will need and can’t get from your usual supplier.

[Update 15-3-2020]

After the first valves were 3D printed using a filament extrusion system, on location at the hospital, more valves were later 3D printed by another local firm, Lonati SpA, using a polymer laser powder bed fusion process (photo below) and a custom polyamide-based material.

[Update 16-3-20]

So many – see comments below – have reached out to offer help in producing these parts, both locally and globally. As far as 3dpbm understands, the model for the valve remains covered by copyright and patents. Hospitals do have a right to produce these parts in an emergency (as in this case) but, in order to legally obtain a 3D printable STL file, the hospital that requires the parts needs to present an official request and the patient usually needs to give consent (this procedure varies according to local regulations). We will continue to update this article as new information becomes available.

[Update 16-3-2020]

The device in question is a Venturi valve, used for a Venturi Oxygen mask. These are low-flow masks that use the Bernoulli principle to entrain room air when pure oxygen is delivered through a small orifice, resulting in a large total flow at predictable FIO2.

[Update 17-3-2020]

In light of the overwhelming response to this topic and offers to help that we have received, we have created an online Emergency AM Forum as a way to help hospitals, AM companies and makers share ideas and unite to fight the COVID-19 pandemic. You can register to create a new topic. Healthcare professionals will be able to use the search by radius function on the right-hand side to find local makers, companies and services that can help. More topics will be added daily.

[Update 18-3-2020]

We have received hundreds of requests for the venturi valve STL file. In this video, Cristian Percassi explains (in Italian) why the STL file has not been shared at this time. The first key reason is that – for the time being – only one hospital had a requirement for about 100 venturi valves and the requirement was fully satisfied with the first production batch. Another hospital may now have a similar need and many hospitals around the world may follow. The correct course of action – Percassi explained – is to always check with the official manufacturer first. If the valves are not available, only in case of a confirmed emergency is it possible to contact a 3D printing service provider and produce a replica. However, a high-end powder bed fusion machine is needed to produce parts that have the necessary accuracy and complexity. Percassi also revealed that, contrary to certain reports, they were never threatened with a lawsuit.

[Update 19-3-2020]

Since the need emerged for venturi valves in ventilators for hospitals around the world dealing with the COVID-19 pandemic, several designers and engineers have started working on creating 3D printable models for them. While there are both copyright issues and medical issues that need to be taken into account when 3D printing any medical product, and a critical one such as a venturi valve, in particular, this case has shown that a life and death situation could warrant using a 3D printable replica. GrabCAD user Filip Kober has now created a model and has made it available for free on the 3D model network. Together with our partners at Shapemode, we have 3D printed it using high accuracy stereolithography technology (see photo below) and the device seems to have proper dimensional accuracy. You can find links to this and all other 3D printable files for useful medical devices in this dedicated section of the Forum. If you use it, please post comments and suggestions for other users.

[Update 21-3-2020]

The Isinnova team now developed and successfully tested a 3D printed adapter to turn a snorkeling mask into a non-invasive ventilator for COVID-19 patients. It’s an idea that anyone can 3D print using just about any type of 3D printer—and could help to address the possible shortage of hospital C-PAP masks for sub-intensive oxygen therapy, which is emerging as a concrete problem linked to the spread of COVID-19: an emergency ventilator mask, produced by adjusting a commercially available snorkeling mask. Download the file here.

[Update 22-3-2020]

A physics simulation was released showing oxygen flow in Revision 4 of Filip Kober’s Venturi’s life-saving nozzle for ventilators in COVID-19 treatment.

Please add/discuss anything useful related to this in the dedicated forum.

THIS ARTICLE WAS ORIGINALLY PUBLISHED ON 3D PRINTING MEDIA NETWORK ON MARCH 14, 2020 BY DAVIDE SHER.